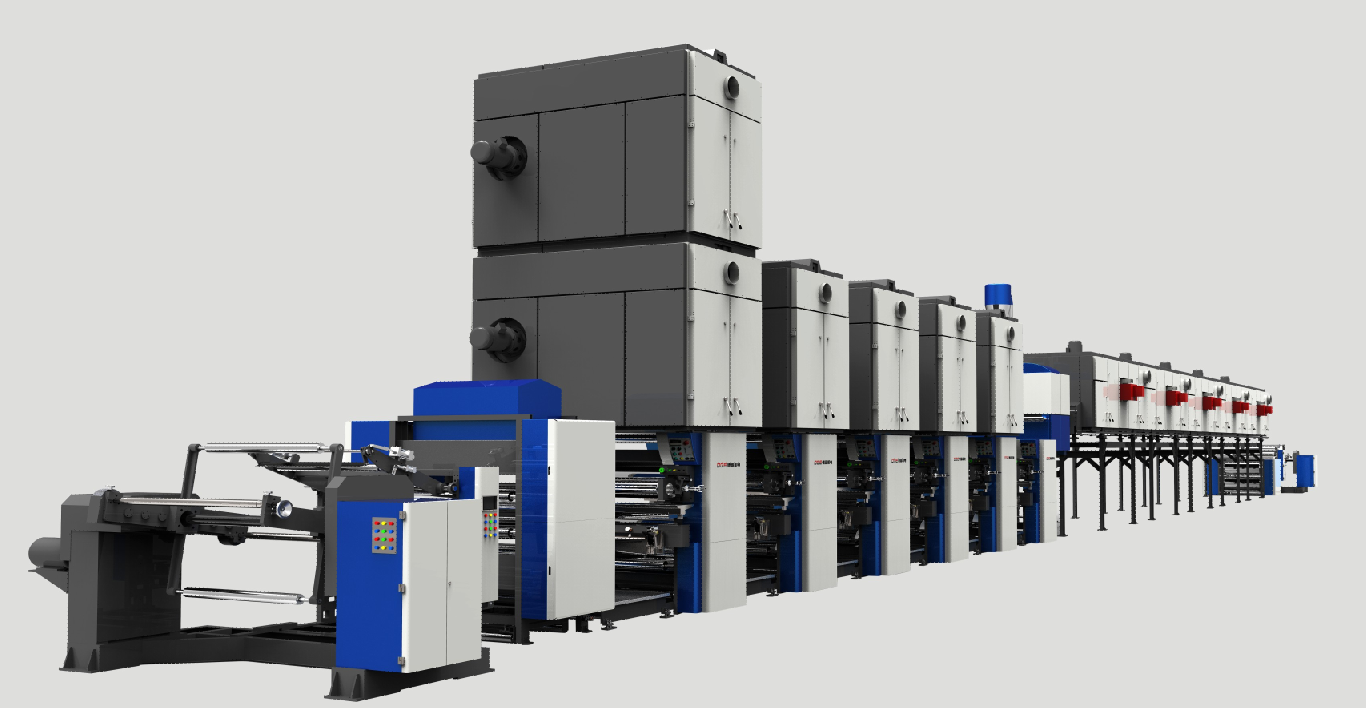

DGE6080 series rotary screen and gravure integrated ink jet printing foaming wallpaper production line

DGE6080 series rotary screen and gravure integrated ink jet printing foaming wallpaper production line

The machine is based on DGE4080 series of rotary screen and gravure integrated foaming wallpaper production line; the combination of digital ink-jet printing technology makes it the new multi-functional high-end wallpaper production line. The machine can complete rotary screen printing, gravure printing, flexography printing, high temperature foaming, embossing, etc. The use of servo drive technology, mechanical structure, and advanced processing technology makes the product performance become advanced in similar foreign products. The machine fully meet the needs of the production of color printing, foaming, embossed wallpaper.

DGE 6080 series of advantage

1、The combination of short road round rotary screen integrated structure and gravure integrated unit realize the shortest paper road.

2、Rotary screen is compatible with the UK bilateral servo drive structure, excellent performance, can meet the big back to printing.

3、Gravure flexo using lateral pressure structure, can according to the technological requirements any swaps.

4、Each printing unit adopted individual servo control and has three servo control points. Tension parameter shows that the control precision is ±5N, so it is stable and reliable with small fluctuations.

5、Efficient vertical oven has effective drying path of 5 meters and can choose either the oil of thermal load or natural gas heating resource.

6、The horizontal oven has reasonable structure, uniform temperature, good foaming effect and can choose either the oil of thermal load or natural gas heating resource.

7、Deep embossing device is servo drive structure with automatically register system and automatic alignment function, with stable register, clear embossing, and high rate of finished products.

8、The machine adopts the new servo drive control system, which is stable and reliable. The automatic alignment function improves the production efficiency and rate of finished goods. The remote diagnosis can be achieved to detect and solve the problems in the shortest time.

Rotary screen and gravure integrated printing units, is equipped with precise double location printing of rotary screen and gravure, efficient drying, and cooling function. Each unit has 3 servo control point, automatic color paste detector and pump, which is fully functional.

Efficient vertical oven, double drying path is up to 10 meters, which provides effective drying conditions for high speed printing. Transmission parts are outside the hot part, to avoid high frequency of maintenance work of the bearing.

DGE6080series main technical parameters

Specifications and models | YLB80 | YLB120 |

Process of round screen printing | Rotary screen printing, gravure printing, flexo printing, foaming, embossing | |

Printing specifications | 530mm、700mm | 530mm、700mm、1060mm |

Repeated circulation | 530mm、640mm、820mm、914mm、1018mm | |

Mechanical speed | 0~100m/min | |

Substrate meterial | 80-200g/㎡wallpaper base paper, non-woven paper 200-600g/㎡wallpaper coated paper | |

Gravure printing error | ≤±0.1mm | |

Screen printing error | ≤±0.2mm | |

Embossing error | ≤±0.25mm | |

Alignment method | Automatic alignment of printing and embossing version | |

24-Hours Hotline

24-Hours Hotline