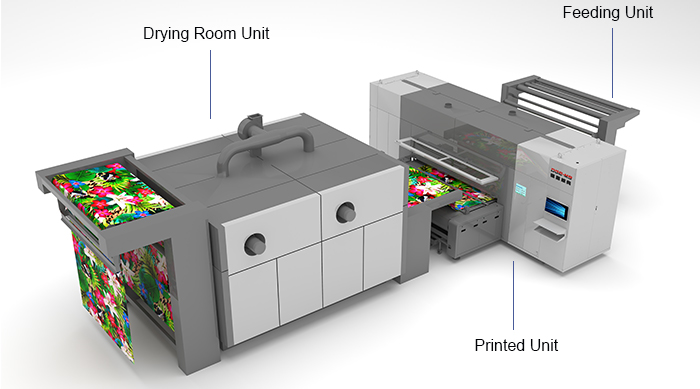

DGE-M9 Series Direct Injection Textile Digital Printing Machine

In 2018, DGE began to develop digital printing machines, aiming to achieve the goal of textile printing, with small batches and multiple types, as well as customized production.

The digital printing machine is controlled by digital technology. It directly outputs the digital pattern files in the computer as physical objects. The ink is sprayed onto the fabric surface through the print head, without the need to create a screen like in traditional printing. This is a non-contact printing method.

Product model | DGE-M929-200 | DGE-M929-240 | DGE-M929-280 | DGE-M929-320 | |

Print head | Type | Japanese industrial print head Ricoh G6 MH5320 | |||

Arrangement | 4×16 | ||||

Quantity/Color | 64 heads/8colors(compatible with 32 heads,48 heads,72 heads) | ||||

Precision | 508x600dpi | 508x600dpi | 508x600dpi | 508x600dpi | |

604x600dpi | 604x600dpi | 604x600dpi | 604x600dpi | ||

635x600dpi | 635x600dpi | 635x600dpi | 635x600dpi | ||

604x900dpi | 604x900dpi | 604x900dpi | 604x900dpi | ||

Guide belt | Habasit | ||||

Max print width | 1850mm | 2250mm | 2650mm | 3050mm | |

Machine speed (8 color mode) | 1 pass | 1690m2/h | 1900m2/h | 2300m2/h | 2600m2/h |

2 pass | 982m2/h | 1150m2/h | 1350m2/h | 1480m2/h | |

3 pass | 700m2/h | 800m2/h | 950m3/h | 1100m2/h | |

Compatible ink | Ink type | Coating,active ink,high-temperature dispersion,acidity | |||

Ink color | Cyan C,magenta M,Yellowy,Black K,Orange O,bright red R,B sapphire blue,G green;optional LM,LC,LK | ||||

Print media | Cotton,linen,silk,wool,chemical fibers,blends and a variety of new fiber woven and knitted fabrics | ||||

Software | Spanish RlP software | ||||

Image Type | file format:TIF/JPG/EPS/PDF,color pattern:RGB/CMYK | ||||

Data Transmission | Gigabit fiber/USB3.0 | ||||

functional | Fabric feeding system | Automatic constant tension feeding Knitted (elastic) fabric feeding system Adjustable Tension Warp Separation and Fabric Feeding System Movable pressure roller | |||

Print head Height | 2~30mmAdjustable)

| ||||

Fabric drying | Hot air drying system | ||||

ink supply system | Industrial-grade negative pressure degassing ink supply,print head ink internal circulation function | ||||

Intelligent cleaning | Automatic cleaning and automatic moisture retention | ||||

Washing system | Double-brush roller,Double clean roller, Double-layer sponge,Intelligent Sprinkler, Water-removing air knife,Multiple drying The magnetic rod collects water | ||||

work environment | Power supply | 380VAC±5%,Three-phase five-wire system,50HZ | |||

Power | Printing system:20KW,Heating system:20-80KW | ||||

Air pressure | 6~8Mpa(manual adjustment) | ||||

Temperature and humidity | Ambient temperature:Recommended 25-30℃ Ambient humidity:Recommended 60-80% | ||||

Dimension & weight | Machine size | 5000*5600*2450 | 5000*6000*2450 | 5000*6400*2450 | 5000*6800*2450 |

Machine weight | 11500 | 12000 | 13000 | 14000 | |

|

|

|

|

Characteristics

● High speed and high precision, with the maximum process speed reaching 100 meters per minute

● 64 printheads, 8 color channels, full-color gamut high-speed printing

● The printhead is designed with multiple protections, ensuring safety and reliability

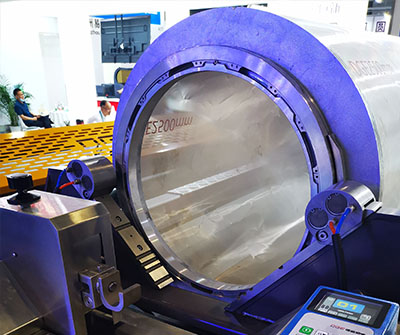

● The unique crossbeam structure ensures the high-precision operation of the magnetic levitation system, which operates smoothly at high speed

● Precision guide belt drive system, positioning accuracy ±0.01mm

● Closed brush guide belt cleaning device, highly efficient and water-saving

● The modular design of the printing module ensures efficient maintenance and calibration

● Ultra-high pattern precision and detailed expressiveness

No plate-making is required. It can perfectly reproduce photo-quality complex images, gradient colors and extremely fine lines, with a very high resolution.

● No pattern repeat restrictions and ultimate flexibility

Theoretically, there is no limit to the length of the pattern, and it is possible to achieve a continuous single large-scale painting.

It is highly suitable for small-batch and personalized customization. Changing patterns only requires switching files on the computer, with zero cost.

● Green and environmentally friendly

On-demand inkjet printing reduces the waste of color paste and the wastewater from screen cleaning in traditional printing. It is called "green print".

● Sample making and production are integrated

It is not only an ideal sample-making device (capable of 100% replicating the effect of bulk goods), but also a perfect tool for small-batch production

24-Hours Hotline

24-Hours Hotline